Airport security screening is in large measure a function of detection of objects and materials. A recurring challenge comes from non-commercial explosives —...

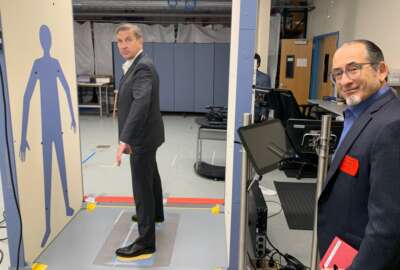

Airport security screening is in large measure a function of detection of objects and materials. A recurring challenge comes from non-commercial explosives — dangerous substances cooked up by criminals for unknown reasons. Before developing technology to detect these substances, the Transportation Security Laboratory, part of the Homeland Security Science and Technology Directorate, must reproduce them in a safe way. That is one of the jobs that falls to the Applied Research Division (ARD). In the fourth and final interview of his series, on location at the lab near Atlantic City, the Federal Drive with Tom Temin spoke with the ARD’s Chemistry Branch Manager, John Brady.

Interview transcript:

John Brady

So with the chemistry branch, we provide a lot of chemistry support services, and one aspect of that is, to support the trace test and evaluation processes that go on. But we also perform, chemical characterization, purity analysis, isotopic enrichment, there’s a lot of different kinds of chemistry based services that we do provide internal and external customers.Tom Temin

And all of that chemistry adds up to what, in the mission itself of, safety.John Brady

When Dr. Ben Wilkins is kind of producing an explosive in his laboratory. One, he’ll kind of perform, small scale safety testing, in his laboratory to make sure it can be handled appropriately. But then, we also perform quality control, on that material, which is typically in the form of kind of spectroscopic analysis, or some sort of chemical analysis. Like chromatography, residual water analysis, residual solvent analysis. Because, you want to make sure that the material that we are making, is what we intended to make. Because, if there’s potentially an impurity there, it could be hazardous, which is not good if you’re going to be handling that material in a Test and Evaluation event. And then two, we want to make sure that the material is being provided to the vendors or being used that test evaluation, is repeatable and reproducible, so it can be a fair valuation.Tom Temin

I guess the question beyond that is, why would you make these things in the first place?John Brady

There’s a lot of different kinds of threats that are out there. Some could be, potentially, military based explosive, some could be commercial based explosives. But there are some explosives that, potentially, could be utilized that don’t have, kind of, a commercial or military use. And when that happens, they are not commercially available. So therefore, we have to make those materials ourselves. So being able to perform chemical analysis, safety testing is, very critical, for ourselves, but also then, in the end to make sure that the product is safe and can be used in a fair and unbiased evaluation of the technologies.Tom Temin

Right. So you’re trying to reproduce things that, bad guys are manufacturing, for whatever purposes they have that might come up to an airplane.John Brady

Potentially, yes. Absolutely.Tom Temin

All right. And to the extent you can, how do you know what people are making out there?John Brady

Our customers would, generally, kind of, give us an idea of what to look for. And they’re going to have their own, specific and unique requirements. And then, we came and develop the test matrix, or develop the materials, or obtain the materials, whether commercially or in house to evaluate it.Tom Temin

Other people, including TSA, the customer, and maybe other intelligence sources, know what is being developed out there in the wild. And so that it comes to you to reproduce it, for purposes of being able to see, if it can be protected against.John Brady

Our customers will have that information and will come to us. And we may not, necessarily, know the exact reason why. We don’t, necessarily, need to know the exact reason why. But we know that it meets their requirements and their needs. So we’re going to make sure that we know how to obtain it, or make it so we can evaluate the technology based on his requirements.Tom Temin

So you have to make it in a really responsible manner, because you have people to protect right in the lab that are making it, and also the vendors that will use it to test in their equipment and so on. Unlike, people that might be making it for a bad purpose. However they make it, wherever they make it, you do it in very controlled conditions, sounds like.John Brady

Yes, we do it in controlled conditions, to ensure our team members are safe. Any vendors or visitors that are coming into laboratory safe, but we also want to try to do it in a, say as, environmentally, friendly way as possible. Because we always had to worry about waste streams and things like that, too.Tom Temin

Right. So then, what is the output? Like, pounds of it, ounces of it, micro amounts of it or what?John Brady

It depends on what the customer’s needs are, and what that requirement is. So we can scale up or down, depending upon what that system or technology is that will be evaluated.Tom Temin

Some of these things, are they stable? I mean, what if it’s unstable? And you have to, say, get into a vendor’s hands? What are some of the ways you can move it, from point A to point B, so that it can be used safely for its intended purposes for testing, and not for actually blowing up?John Brady

That’s a good question. We have, actually, have a scale up process here at the laboratory. So if we’re trying to work with something that may be unstable, we actually, determine first, is it stable or not stable? And we use small scale safety testing, which uses a variety of different techniques, everything from impact, friction, electrostatic discharge, like the static shock if you touch the door. And we, kind of, determine the various stimuli that is sensitive too. Along that lines, we use thermal analysis to help, kind of, determine how stable material, potentially, could be, kind of, just based on its thermal properties. And all this information is considered. And then we can develop processes, on how to potentially mitigate a material, or defined timelines, for how long a material could be potentially used for. So, it can be used in that safe manner for that defined timeframe. After that timeframe, we then take it back, and essentially destroy that material or solvate it. So that is no longer unstable, rendered safe. And we can always repeat this whole process, and make more, so that it can, kind of, restart that timeline again.Tom Temin

And do you have a sense of how many of these things are out there, in the wild? When it comes to commercial explosives, which are available commercially, because they have purposes for moving mountains to make roads, or whatever the case might be, then you know what’s there. But for the inventiveness of terrorists, for example, are there tens, thousands, hundreds of types of explosives they’re making?John Brady

There’s a lot of different types of varieties. And that’s why we have our Applied Research Division, here at the laboratory, to investigate the potential combinations that are out there, and provide that information to our customers.Tom Temin

Do you ever come across something that you develop and make reproduce, and say, this actually could have a commercial purpose?John Brady

I don’t think we have kind of looked at it terms that, whether it has a commercial application or not. But, we will make those materials and provide that data to the customer, for all the various properties that it has.Tom Temin

And what are the skill sets and educational backgrounds required to do this kind of work?John Brady

So we, typically, have a mix of physicists, engineers and chemists that work here at the laboratory. And we have everyone, from associate’s degrees to PhDs, that work here at the laboratory.Tom Temin

Yeah, and so it sounds like you have, a pretty dedicated bunch, because industrial chemists can get big fancy jobs at big fancy corporations here, they’re working in an old warehouse.John Brady

That is correct. A lot of people care about the mission, because you’re able to come here, and you’re able to contribute, which is meaningful to me and meaningful to people, to be able to kind of contribute to protecting the public and homeland security. So, there’s a lot of drawl, to be able to do that and do what we do.Tom Temin

And just to be clear, when you develop something, because you know this is being made out there, and now you’ve reproduced it. From your operation, then it becomes something to go to another operation, to see if it can be detected, say, by spectroscopy for operational use, at some point to test, hey, what’s in that bottle going through a screening line?John Brady

Yeah, there’s multiple avenues for the material. So, if Dr. Wilkins produces a material in his laboratory, that could, potentially, then be handed off to my laboratory for characterization. It could also be then passed off to Dr. Broderick’s laboratory, where it could be formulated into, some trace standards, which can be then passed along to our testing evaluation teams. Or it could be passed, kind of, directly to our evaluation teams, for analysis if they’re looking at something more bulk versus trace.Tom Temin

So a trace means a very tiny amount can be detected, which could indicate there’s more of it somewhere nearby.John Brady

It traces, typically, we define as invisible to the naked eye. So it’s looking for, kind of small particles, that you cannot, typically, see with your naked eye. And is indicative of potential interaction with a threat material of interest.Tom Temin

Got it. And do these things take the form of liquids, gels, solids, gases?John Brady

So typically, the threats can be in any multitude of phases. Typically, you will have solid phase, but you can also have liquid based explosives. Now, you can also detect explosives in the gas phase, but you don’t necessarily have an explosive in the gas phase. But you can have explosions, based on the flashpoint.Tom Temin

You must be really consulted by the neighborhood for science experiments.John Brady

Actually, working with our, kind of, Communication Outreach Department, locally here at the TSL. They have started to look at potential opportunities, to work with universities and high schools and grammar schools, to try to get us out there in the field and do some STEM or STEAM type activities.Tom Temin

Sure. So the kids that want to get away from baking soda and vinegar, they come to you.John Brady

That’s one potential option. Yes.

Copyright © 2025 Federal News Network. All rights reserved. This website is not intended for users located within the European Economic Area.

Tom Temin is host of the Federal Drive and has been providing insight on federal technology and management issues for more than 30 years.

Follow @tteminWFED